The most common material for indoor basketball courts is maple hardwood. Maple is known for its durability, smooth surface, and ability to provide excellent traction and ball bounce. Engineered wood and synthetic materials like vinyl or rubber can also be used in certain types of courts, but hardwood is the preferred choice for professional and high-performance courts.

Maple hardwood is preferred because of its hardness, fine grain, and durability. It provides the ideal level of traction for players, helping reduce slips and falls. The smooth surface also enhances ball control and bounce, which is essential for the fast-paced nature of basketball.

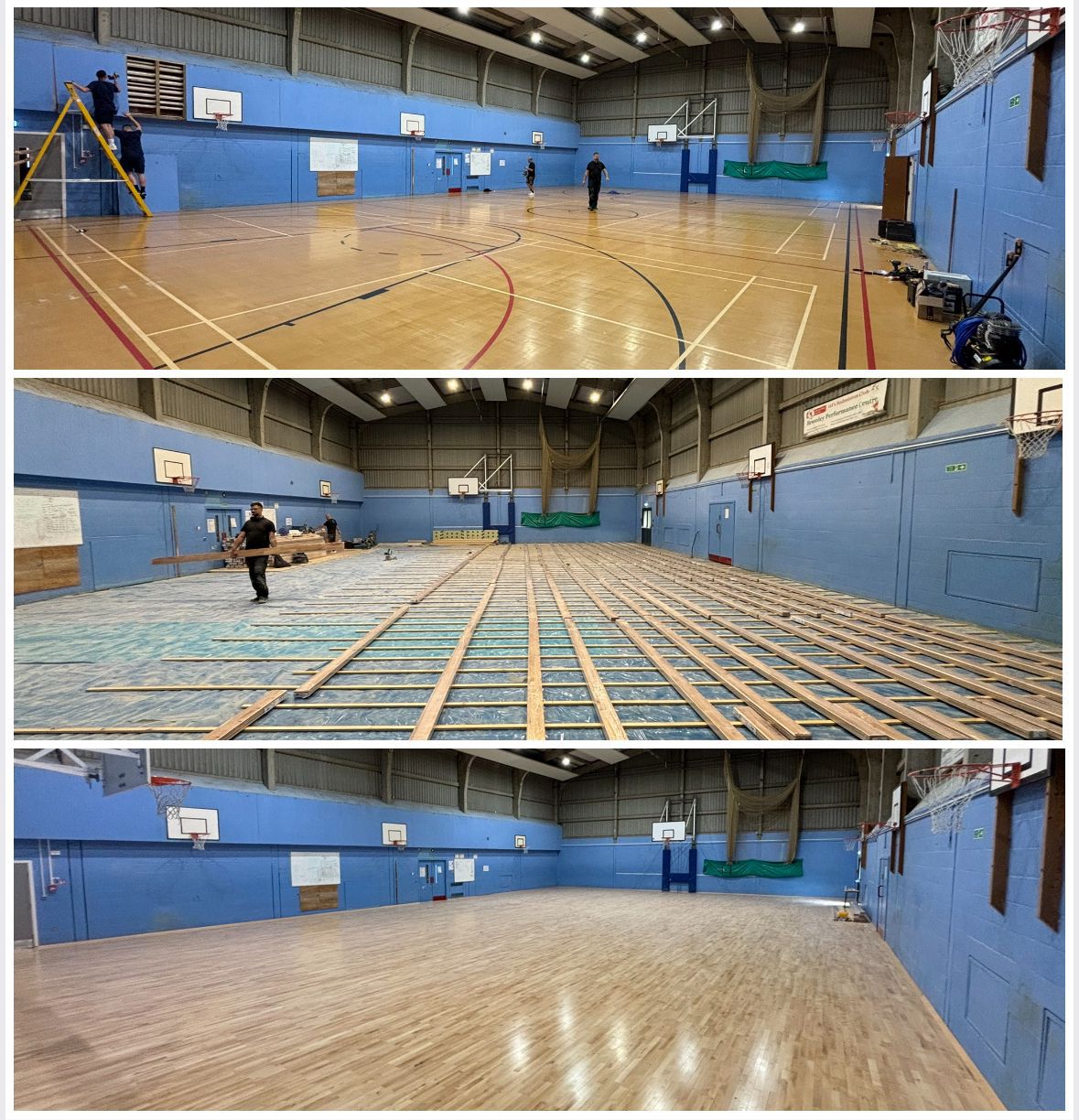

The time required to construct a basketball court floor depends on the size of the court and the materials used. On average, installation of a hardwood floor can take between 1 to 3 weeks, including the preparation of the subfloor, installation of the wood surface, sanding, and finishing. Additional time may be needed for the finish to cure before the court is ready for use.

Most basketball courts use a resilient subfloor system to provide shock absorption and improve the safety and performance of players. Subfloor systems often include cushioned sleepers or resilient pads that help absorb impact, reduce the risk of injury, and enhance the flexibility of the floor.

Yes, basketball court floors can be customised with logos, team colours, and court markings such as the key, three-point line, and free-throw line. After the floor is installed and sanded, we apply high-quality paint for court markings and branding. These customisations are sealed with a protective finish to ensure durability.

The frequency of refinishing depends on the level of use, but it’s generally recommended to refinish a basketball court floor every 5 to 10 years. Regular refinishing helps maintain the floor’s protective layer, ensuring durability and optimal performance. For heavily used courts, more frequent refinishing may be needed to restore the floor’s shine and performance characteristics.

To maintain a basketball court floor, regular cleaning is essential to remove dust, debris, and sweat that can damage the surface. Sweeping or vacuuming the floor daily and mopping it with a wood-safe cleaner will help preserve its finish. Players should also wear non-marking shoes to prevent scuff marks, and heavy equipment should be moved with care to avoid scratches.

A well-constructed basketball court floor with the right materials and subfloor system provides excellent shock absorption, reducing the impact on players’ joints and muscles. A smooth, well-finished floor also reduces the risk of slips, trips, and falls, ensuring a safer playing environment for athletes.

Hardwood basketball floors, typically made from maple, are the industry standard for professional and competitive play due to their durability, traction, and ball response. Synthetic floors, made from materials like vinyl or rubber, offer more cushioning and are often used in multi-purpose facilities or outdoor courts. However, synthetic floors do not provide the same level of ball bounce and player performance as hardwood.

With proper maintenance and care, a hardwood basketball court floor can last for several decades. Regular cleaning, refinishing, and occasional repairs are necessary to ensure that the floor remains in optimal condition and continues to perform well over time.

Yes, we can install basketball court floors in multi-purpose gyms. In such cases, we recommend using materials that can withstand a variety of activities, such as engineered wood or synthetic surfaces that provide durability and flexibility for multiple uses. Court markings can also be customised to suit the gym’s other functions.

The cost of installing a basketball court floor depends on several factors, including the type of materials used (hardwood vs synthetic), the size of the court, and any customisations such as logos or court markings. We provide detailed estimates based on your specific needs during the consultation process.

We typically use water-based or oil-based polyurethane finishes for basketball court floors. Water-based finishes dry quickly and have low odour, making them ideal for facilities that require quick turnaround times. Oil-based finishes provide a deeper, richer look, but take longer to dry. Both finishes are durable and provide excellent protection for the floor.

Our team uses precise measurements and high-quality stencils to apply court markings such as the key, free-throw line, and three-point arc. These markings are painted with durable, long-lasting paint and sealed with a protective finish to ensure they remain clear and vibrant even after heavy use.

Ryans Restoration offers expert basketball court floor construction services with a focus on quality, safety, and performance. Our experienced team works closely with you to design and install a court that meets your specific needs, whether for recreational, school, or professional use. We use high-quality materials and state-of-the-art installation techniques to ensure that your court provides the best possible experience for players and spectators alike.