In the bustling environment of a commercial kitchen, safety is paramount yet often overlooked until an incident occurs. Imagine the chaos of a slip on a greasy floor during a peak service hour—it’s a catastrophe waiting to happen. This is why anti-slip treatments are not just an option but a necessity for wood floors in commercial kitchens, where wet and greasy conditions can transform routine work into hazardous encounters. Investing in products like Dura Grip and Tuff Grip can significantly enhance safety, mitigate risks, and ensure a seamless operation, safeguarding both employees and businesses.

Understanding Anti-Slip Treatments for Commercial Kitchen Wood Floors

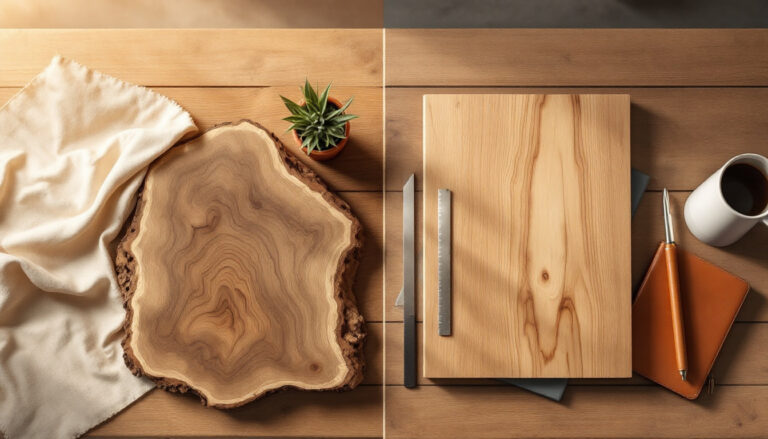

In commercial kitchens, the bustling environment coupled with wet and greasy conditions makes slips and falls a significant safety concern. Anti-slip treatments for wood floors play a crucial role in enhancing safety by providing additional traction. This is particularly important in high-traffic kitchen areas where the risk of accidents is elevated. These treatments are specifically designed to address the unique challenges posed by wooden surfaces, offering solutions that improve slip resistance and ensure the safety of both employees and customers.

Popular anti-slip products like Dura Grip and Tuff Grip are frequently chosen for their effectiveness in enhancing traction on wood floors. Dura Grip offers a robust solution known for its durability and ability to withstand heavy foot traffic, making it ideal for busy kitchen environments. Tuff Grip, on the other hand, provides a versatile application suitable for a variety of wooden surfaces, ensuring comprehensive coverage and protection. Both products are designed to improve grip and reduce slip hazards, contributing to a safer working environment.

When selecting an anti-slip treatment for wood floors, it is essential to evaluate several factors to ensure the chosen product meets the specific needs of the kitchen environment. Considerations should include the treatment’s effectiveness in improving slip resistance, its durability under frequent use, and the maintenance requirements necessary to sustain its efficacy. Additionally, the impact on the aesthetics of the wood floors and cost considerations should be assessed to make an informed decision.

- Effectiveness

- Durability

- Maintenance requirements

- Impact on aesthetics

- Cost considerations

Evaluating Different Anti-Slip Treatment Products

When it comes to enhancing safety in commercial kitchens, selecting the right anti-slip treatment for wood floors is essential. Various product types, including non-slip floor coatings, paints, and tapes, offer unique benefits tailored to improve slip resistance and overall safety. Non-slip coatings are designed to create a textured surface, enhancing traction on wooden floors, while non-slip paints provide a durable finish that can withstand the rigours of a busy kitchen environment. Anti-slip tapes, on the other hand, are a practical solution for specific high-risk areas, allowing targeted slip prevention without the need for extensive application across the entire floor. Each of these options comes with distinct application processes and levels of effectiveness, making it crucial to evaluate which product best suits the specific needs of the commercial kitchen setting.

| Product Name | Application Process | Suitability | Cost |

|---|---|---|---|

| Stone Grip | Applied with a mop or brush | Suitable for areas exposed to water | Moderate |

| Polish Grip | Spray application | Ideal for polished wood surfaces | Higher |

| Clear Spray | Spray-on method | Versatile for various surfaces | Lower |

Selecting the appropriate anti-slip treatment involves more than just understanding the products available; it requires a thorough assessment of the kitchen environment and specific floor treatment options. Considerations such as the level of foot traffic, exposure to moisture, and the type of wood flooring should guide the decision-making process. Products like Stone Grip are well-suited for wet areas, providing enhanced traction where it’s most needed, while Polish Grip is perfect for maintaining the aesthetic of polished surfaces. Ultimately, choosing the right slip-prevention method not only ensures compliance with safety standards but also contributes to a safer workplace by effectively reducing the risk of slips and falls in commercial kitchens.

Application Techniques and Maintenance for Anti-Slip Treatments

The effectiveness of anti-slip treatments for wood floors in commercial kitchens hinges significantly on the correct application techniques. Properly applied treatments ensure enhanced traction and long-term benefits. For large areas, DIY applications are feasible, but professional installation is often recommended to achieve the best results. Professionals possess the expertise to handle intricate details and ensure that the treatment adheres correctly to the wood surface, thereby maximising slip resistance. Attention to detail during application, such as ensuring even coverage and selecting the right product for the wood type, is crucial in preventing slips and maintaining safety standards in a busy kitchen environment.

Ongoing maintenance is equally vital in sustaining the slip resistance of treated wood floors. Regular upkeep not only prolongs the effectiveness of the anti-slip treatment but also ensures that the flooring continues to meet safety requirements. Routine cleaning to remove debris and dirt prevents surface wear, while periodic reapplication of anti-slip products may be necessary to maintain their effectiveness. Regular inspections should be conducted to identify and promptly address any signs of wear or damage. It’s important to use cleaning agents that are compatible with the treatment, as harsh chemicals can deteriorate the anti-slip properties and compromise floor safety.

- Regular cleaning to remove debris

- Periodic reapplication of treatments

- Inspection for wear and tear

- Avoiding harsh cleaning chemicals

Safety Regulations and Compliance for Kitchen Flooring

Adhering to safety regulations is paramount when treating wood floors in commercial kitchens. Compliance with established floor safety standards is crucial to prevent accidents and avoid potential legal issues. These regulations are designed to ensure that both employees and customers are protected from slip-and-fall hazards, which are common in high-traffic kitchen environments. By following these standards, commercial kitchens can maintain a safe workplace, reducing the risk of injuries and associated liabilities.

Slip testing results play a vital role in evaluating the effectiveness of anti-slip treatments. These tests provide objective data on the slip resistance of treated surfaces, helping businesses choose the most suitable solution for their specific needs. By incorporating slip testing into the decision-making process, commercial kitchens can ensure that the selected treatments meet safety requirements and perform reliably under kitchen conditions. This data-driven approach not only enhances safety compliance but also contributes to a safer and more efficient working environment.

Cost Considerations and Expert Recommendations

Cost-effectiveness is a vital consideration when selecting anti-slip treatments for wood floors in commercial kitchens. Balancing the initial investment with the benefits and longevity of the treatment ensures that the solution is both economical and effective. What is the most cost-effective anti-slip treatment? Precision in choosing a treatment that provides durable slip resistance without frequent reapplication is essential. High-quality treatments may have a higher upfront cost but often result in long-term savings by reducing maintenance expenses and minimising the risk of accidents. Evaluating the cost against the potential benefits, including enhanced safety and reduced liability, is crucial for effective budget management in a commercial kitchen setting.

Expert recommendations play a significant role in guiding purchasers towards the best anti-slip solutions tailored to their specific needs. Ryan’s Restoration offers valuable insights and professional advice based on extensive experience in floor treatments. Why consult professionals like Ryan’s Restoration? Expert guidance ensures that the chosen treatment aligns with the kitchen’s unique requirements, taking into account factors such as foot traffic, moisture levels, and wood type. Additionally, professionals provide access to high-quality, reliable products and ensure correct application, optimising the treatment’s effectiveness and longevity. This expert approach not only enhances kitchen safety but also contributes to efficient and effective maintenance practices.

- Tailored advice for specific environments

- Access to high-quality, reliable products

- Professional application and maintenance services

Final Words

Choosing the right anti-slip treatments for wood floors in commercial kitchens is paramount. These solutions not only enhance safety but also preserve the aesthetic of the flooring. Selecting the appropriate product, be it Dura Grip, Tuff Grip, or others, requires a thorough evaluation of effectiveness and maintenance demands.

The importance of adhering to safety regulations and consulting experts like Ryan’s Restoration cannot be overstated. With professional guidance, businesses can achieve a safe, durable, and cost-effective flooring solution, ensuring both worker and customer safety. Embrace these treatments for a safer kitchen experience.

FAQ

Q: What are the best anti-slip treatments for wood floors in commercial kitchens?

Anti-slip treatments such as Dura Grip and Tuff Grip are designed to enhance traction on wood floors in commercial kitchens, ensuring safety where slip risks are prevalent.

Q: How can I find anti-slip treatments for wood floors in commercial kitchens near me?

To find anti-slip treatments locally, consider searching online directories or contacting floor treatment professionals in your area for tailored safety solutions.

Q: How much do anti-slip treatments for wood floors in commercial kitchens cost?

The cost of anti-slip treatments varies based on factors like product type and application size. Consult suppliers for detailed pricing tailored to your commercial kitchen needs.

Q: What type of flooring is best for commercial kitchens?

Vinyl flooring is commonly recommended for commercial kitchens due to its durability, ease of maintenance, and slip-resistant properties, making it a practical choice.

Q: How do you make wood floors slip-resistant in a restaurant kitchen?

To make wood floors slip-resistant, apply specialised anti-slip treatments or coatings designed to enhance traction and reduce slip risks in high-traffic areas.

Q: How can you seal wood floors in a kitchen for better safety?

To seal wood floors for improved safety, use a compatible finish that enhances durability while maintaining slip resistance, ensuring long-term protection and effectiveness.